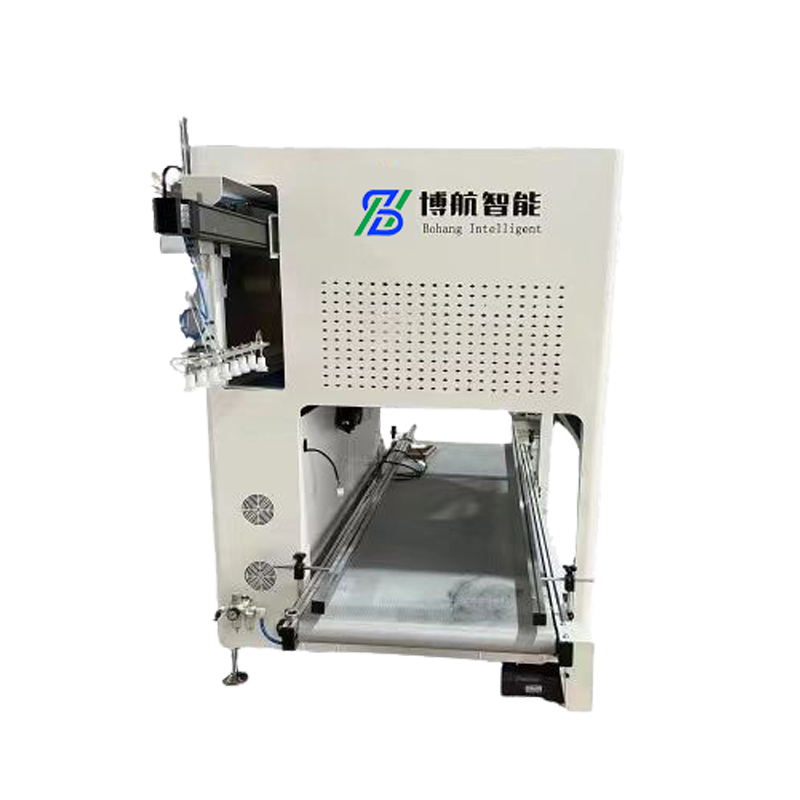

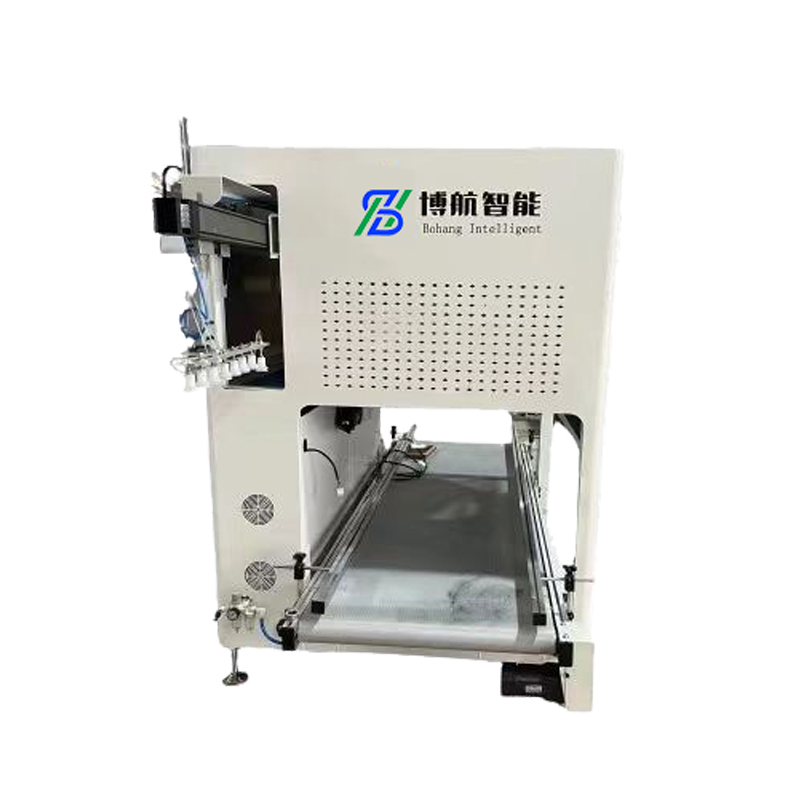

Automatic Bottle Packing Machine

- Product Information

The Automatic Bottle Packing Machine is a highly automated industrial device designed specifically for efficient and precise packaging of various bottled products. It utilizes advanced mechanical and electrical control systems to automate the entire process, from bottle conveying, filling, sealing, to final packaging. Widely used across multiple industries, this machine significantly improves production efficiency, reduces labor costs, and ensures consistent and stable packaging quality. Its core function is to enable rapid and accurate packaging of bottled products, making it an indispensable piece of equipment in modern industrial production.

Automatic Bottle Packing Machine Features:

1. High Efficiency:

The Automatic Bottle Packing Machine utilizes advanced servo motor drive technology, capable of achieving a packaging speed of up to 12,000 bottles per hour, significantly exceeding traditional packaging methods. Its high-speed conveyor and precise positioning system ensure that each bottle is correctly positioned for filling and sealing. Furthermore, the machine's multi-station design allows for multiple packaging processes to be performed simultaneously, significantly improving overall production efficiency. For example, in the beverage industry, this machine can complete large quantities of beverage bottles in a short period of time, meeting the needs of large-scale production.

2. Accuracy:

Equipped with high-precision sensors and control systems, the machine precisely controls the fill level and seal quality of each bottle. With a filling accuracy of ±0.5%, the machine ensures consistent fill levels for each bottle, eliminating product quality issues caused by uneven filling levels. The sealing process utilizes advanced hot-melt technology, achieving a seal strength of 150N/cm², effectively preventing leakage. In the pharmaceutical industry, this high level of accuracy is crucial for ensuring drug quality and safety.

3. High Adaptability:

The Automatic Bottle Packing Machine is highly adaptable, capable of handling bottles of varying shapes, sizes, and materials. Its adjustable gripper and conveying system can be quickly adjusted to the specific bottle size without requiring extensive component replacement. For example, the machine can easily handle bottles ranging from small 30mm diameter bottles to large 100mm diameter bottles. Furthermore, it supports a variety of packaging materials, such as plastic and glass, to meet the needs of various industries.

4. Intelligent:

The machine features an advanced built-in PLC control system with intelligent fault diagnosis. If an error occurs, the system automatically shuts down and displays a fault code, enabling technicians to quickly locate and resolve the issue. The machine also supports remote monitoring and data collection, allowing users to view the machine's operating status and production data in real time via mobile phones or computers, enabling intelligent management.

5. Environmental Protection and Energy Saving:

Environmental protection and energy conservation were fully considered in its design. The Automatic Bottle Packing Machine utilizes an energy-saving motor and optimized mechanical structure, reducing energy consumption by 30% during operation. Furthermore, the waste generated during the packaging process can be effectively recycled, reducing environmental pollution. For example, in the food industry, this environmentally friendly and energy-saving feature helps companies reduce production costs while enhancing their sense of social responsibility.

Automatic Bottle Packing Machine Applications:

1. Food Industry:

In the food industry, the Automatic Bottle Packing Machine is widely used for packaging products such as beverages, sauces, and condiments. It can quickly fill and seal various liquid or semi-fluid foods into bottles, ensuring their freshness and safety. For example, in the beverage production process, this machine can efficiently fill and seal carbonated drinks and juices, meeting consumer demand for high-quality food.

2. Pharmaceutical Industry:

The pharmaceutical industry places extremely high demands on packaging precision and safety. The Automatic Bottle Packing Machine can precisely control the filling volume of liquid medicines, ensuring the correct dosage in each bottle. Its sealing technology also effectively prevents moisture and contamination, ensuring the quality and expiration date of the medicines. For example, this machine provides a reliable packaging solution for the production of eye drops, oral solutions, and other medications.

3. Cosmetics Industry:

The cosmetics industry prioritizes product appearance and packaging quality. Automatic bottle packing machines can adapt to various cosmetic bottle shapes and materials, creating attractive and secure packaging. For example, when packaging products like perfumes and serums, these machines ensure exquisite packaging and a tight seal, enhancing the product's market competitiveness.

4. Chemical Industry:

Chemical products are often hazardous, requiring particular care in packaging. Automatic bottle packing machines can handle a variety of chemical liquids, such as detergents and lubricants, ensuring no leakage or contamination during the packaging process. Their robust structure and reliable sealing technology ensure the safe transportation and storage of chemical products.

5. Daily Necessities Industry:

In the daily necessities industry, the packaging of products like shampoo and shower gel is also essential for automatic bottle packing machines. They efficiently fill and seal these products, ensuring product quality and user experience. For example, when producing large-volume shampoo bottles, these machines can quickly and accurately complete packaging tasks to meet market demand.

Automatic Bottle Packing Machine Maintenance:

1. Daily Cleaning:

After each day's work, wipe the surface of the Automatic Bottle Packing Machine with a soft cloth and detergent to remove dust and residue. Pay special attention to cleaning the conveyor belt, filling head, and sealing section to prevent residue from affecting normal operation. Regularly inspect the machine's seals and replace any damaged parts promptly to prevent leakage.

2. Regular Inspections:

Weekly inspect key components of the machine, including the motor, sensor, and drive belt. Check the motor's operating sound, sensor sensitivity, and drive belt for wear. Any abnormalities should be adjusted or replaced promptly. Also, check the machine's lubrication system to ensure sufficient and clean lubricant to prevent equipment failure due to insufficient lubrication.

3. Accuracy Calibration:

Monthly, calibrate the machine's filling accuracy and sealing strength. Use a standard measuring cup and pressure tester to check whether the fill volume meets the set value and that the sealing strength meets industry standards. If any deviations are found, adjust the machine's parameter settings promptly. Additionally, regularly inspect the machine's positioning system to ensure that bottles are accurately positioned during conveying and packaging.

4. Preventive Maintenance:

Perform comprehensive preventive maintenance on the Automatic Bottle Packing Machine every quarter. This includes inspecting the machine's electrical system, cleaning dust and debris, and checking for aging or damage to the wiring. Deep cleaning and lubrication of mechanical components are performed, and worn parts are inspected and replaced. Preventive maintenance effectively extends the machine's service life and reduces the occurrence of unexpected failures.

5. Operator Training:

Regular operator training is provided to ensure they are familiar with the Automatic Bottle Packing Machine's operating procedures and maintenance. Operators should be aware of common equipment failures and their solutions, enabling them to take timely action when an abnormality occurs. This training enhances operator skills, reduces equipment damage caused by improper operation, and ensures normal operation.